The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

The printed parts are very similar to forged parts but has higher densification, virtually eliminating voids and porosity, does not have a grain like billet material making it stronger, and parts are unlimited in shape. The work/print part envelope is 36” X 20” X 20”.

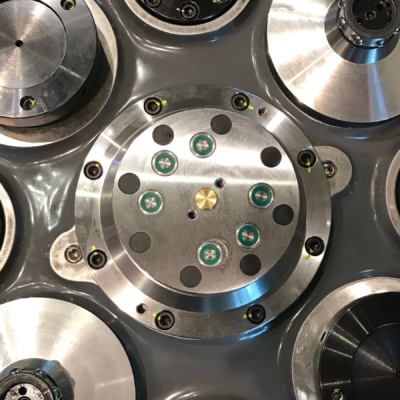

When parts are not being printed the CNC machine performs everyday machine operations producing traditional production parts. Also, all standard accessories can be added as well. Some are, 4th axis, rotary tables, vises, three jaw chucks, and other fixtures.

➢ The WLMD process eliminates the safety hazards of powder deposition methods

➢ Reduces material costs as parts are printed to a “near net finish” (within .040”) eliminating removal of excess material, and reducing Cycle Time, labor, and power consumption costs.

➢ Eliminates costs of Work Holding fixtures & reduces Set Up time.

➢ A part can be made using two different metals, i.e. mild steel as a core metal while the outside is finished with titanium using the “Twin Wire” function.

➢ WLMD parts have fewer voids – 99.9998% denser than forgings or castings.

➢ Enables parts to be made with internal passageways for gas or liquid flow.

➢ Allows prototype parts to be made in hours rather than days or weeks.

➢ No billet needed; all parts can be printed from wire, eliminating sawing and reducing required storage.

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 19.69 | 23.62 | 31.50 |

| Y Axis | in | 16.54 | 19.69 | 31.50 | |

| Z Axis | in | 14.96 | 19.69 | 31.50 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 1,890 | 2,362 | 2,362 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | in | 14.96 | 15.75 | 19.69 | |

| Depth | in | 14.96 | 15.75 | 19.69 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | lb | 440 | 880 | 1,320 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 30 | 30 | 30 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | lb | 15.4 | 15.4 | 24.2 | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | 2.95 | 3.74 | |

| Max Tool Dia. - Adj. Empty | in | 4.92 | 4.92 | 7.87 | |

| Max Tool Length | in | 9.84 | 11.81 | 15.75 | |

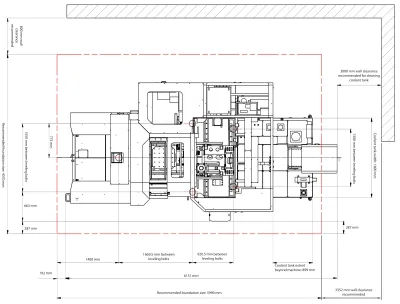

| DIMENSIONS | Machine Weight | lb | 7,700 | 12,100 | 29,700 |

| Width | in | 59 | 96 | 122 | |

| Depth | in | 99 | 141 | 240 | |

| Height | in | 97 | 108 | 119 | |

| Current | kVA | 30 | 40 | 45 | |

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 500 | 600 | 800 |

| Y Axis | mm | 420 | 500 | 800 | |

| Z Axis | mm | 380 | 500 | 800 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 48 | 60 | 60 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | mm | 380 | 400 | 500 | |

| Depth | mm | 380 | 400 | 500 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | kg | 200 | 400 | 600 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 22 | 22 | 22 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | kg | 7 | 7 | 11 | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | 75 | 95 | |

| Max Tool Dia. - Adj. Empty | mm | 125 | 125 | 200 | |

| Max Tool Length | mm | 250 | 300 | 400 | |

| DIMENSIONS | Machine Weight | kg | 3,500 | 5,500 | 13,500 |

| Width | mm | 1500 | 2420 | 3100 | |

| Depth | mm | 2500 | 3600 | 6100 | |

| Height | mm | 2450 | 2750 | 3000 | |

| Current | kVA | 30 | 40 | 45 | |

Jupiter partners with the world’s leading CNC system providers to deliver whatever platform you prefer.

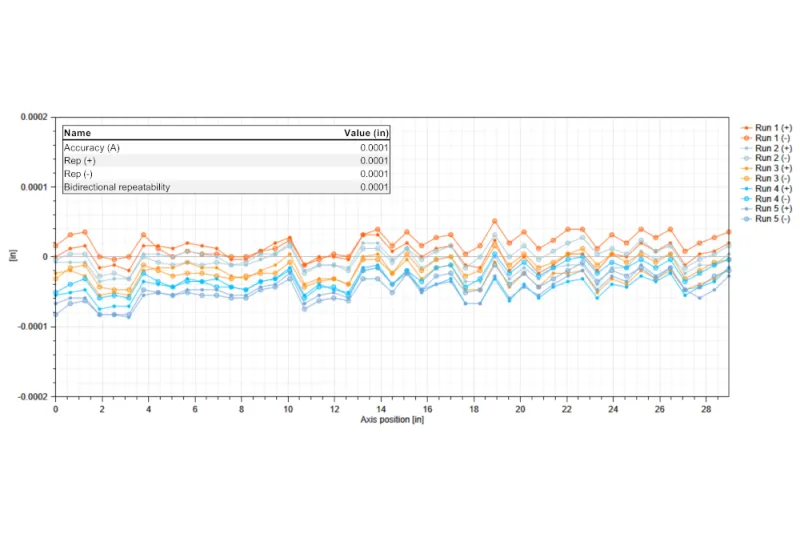

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.