The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

The VMX650-FX WLMD Vertical Machining Center is a high-performance, premium machine tool designed to meet the demands of various industries, including aerospace, defense, medical, and automotive. This advanced 5-axis milling machine integrates fully with a Wire Laser 3D Metal Printing head, allowing parts to be printed and machined in the same setup, significantly reducing production time and increasing accuracy.

The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

The VMX650-FX WLMD Vertical Machining Center is a high-performance, premium machine tool designed to meet the demands of various industries, including aerospace, defense, medical, and automotive. This advanced 5-axis milling machine integrates fully with a Wire Laser 3D Metal Printing head, allowing parts to be printed and machined in the same setup, significantly reducing production time and increasing accuracy.

The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

The printed parts are very similar to forged parts but has higher densification, virtually eliminating voids and porosity, does not have a grain like billet material making it stronger, and parts are unlimited in shape. The work/print part envelope is 36” X 20” X 20”.

The NEW JUPITER VMC4024-WLMD is a Premium Hybrid Additive-Subtractive CNC machine center which combines high performance speed and accuracy with an integrated Wire Laser Metal Deposition (WLMD) patented system by MELTIO. The new Jupiter CNC Machine Additive System is “Power by Meltio” and prints 3D metal parts using wire not powder. The WLMD system offers a selection of 14 different metal types such as Mild steel, Stainless Steel, Alloy Steels, Titanium, and others. The 3D part is printed to a “Near Net Finish” (within .040”) shape which dramatically reduces machine cycle time, fixtures, design and machined work holding, tooling, and setup time.

The printed parts are very similar to forged parts but has higher densification, virtually eliminating voids and porosity, does not have a grain like billet material making it stronger, and parts are unlimited in shape. The work/print part envelope is 36” X 20” X 20”.

When parts are not being printed the CNC machine performs everyday machine operations producing traditional production parts. Also, all standard accessories can be added as well. Some are, 4th axis, rotary tables, vises, three jaw chucks, and other fixtures.

The JUPITER VMX650 FX WLMD Vertical Machining Center is a high-performance, premium machine tool designed to meet the demands of various industries, including aerospace, defense, medical, and automotive. This advanced 5-axis milling machine integrates fully with a Wire Laser 3D Metal Printing head, allowing parts to be printed and machined in the same setup, significantly reducing production time and increasing accuracy.

With its compact footprint, the VMX650 FX WLMD offers a powerful platform that supports maximum capacity and performance. Its design is automation-friendly, with front and side accessibility, and it includes options for pallet pools, making it an ideal choice for high-efficiency manufacturing environments.

Crafted with top-quality components, from the castings to the spindle bearings, Jupiter ensures years of flawless operation. The machining center’s exceptional machining volume, relative to its floor space, guarantees optimal performance and space efficiency. Stay tuned for an updated image showcasing the latest features of this versatile and high-performance machine.

Experience the future of manufacturing with the JUPITER VMX650 FX WLMD, where precision, performance, and cutting-edge technology converge.

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 19.69 | 23.62 | 31.50 |

| Y Axis | in | 16.54 | 19.69 | 31.50 | |

| Z Axis | in | 14.96 | 19.69 | 31.50 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 1,890 | 2,362 | 2,362 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | in | 14.96 | 15.75 | 19.69 | |

| Depth | in | 14.96 | 15.75 | 19.69 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | lb | 440 | 880 | 1,320 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 30 | 30 | 30 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | lb | 15.4 | 15.4 | 24.2 | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | 2.95 | 3.74 | |

| Max Tool Dia. - Adj. Empty | in | 4.92 | 4.92 | 7.87 | |

| Max Tool Length | in | 9.84 | 11.81 | 15.75 | |

| DIMENSIONS | Machine Weight | lb | 7,700 | 12,100 | 29,700 |

| Width | in | 59 | 96 | 122 | |

| Depth | in | 99 | 141 | 240 | |

| Height | in | 97 | 108 | 119 | |

| Current | kVA | 30 | 40 | 45 | |

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 500 | 600 | 800 |

| Y Axis | mm | 420 | 500 | 800 | |

| Z Axis | mm | 380 | 500 | 800 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 48 | 60 | 60 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | mm | 380 | 400 | 500 | |

| Depth | mm | 380 | 400 | 500 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | kg | 200 | 400 | 600 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 22 | 22 | 22 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | kg | 7 | 7 | 11 | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | 75 | 95 | |

| Max Tool Dia. - Adj. Empty | mm | 125 | 125 | 200 | |

| Max Tool Length | mm | 250 | 300 | 400 | |

| DIMENSIONS | Machine Weight | kg | 3,500 | 5,500 | 13,500 |

| Width | mm | 1500 | 2420 | 3100 | |

| Depth | mm | 2500 | 3600 | 6100 | |

| Height | mm | 2450 | 2750 | 3000 | |

| Current | kVA | 30 | 40 | 45 | |

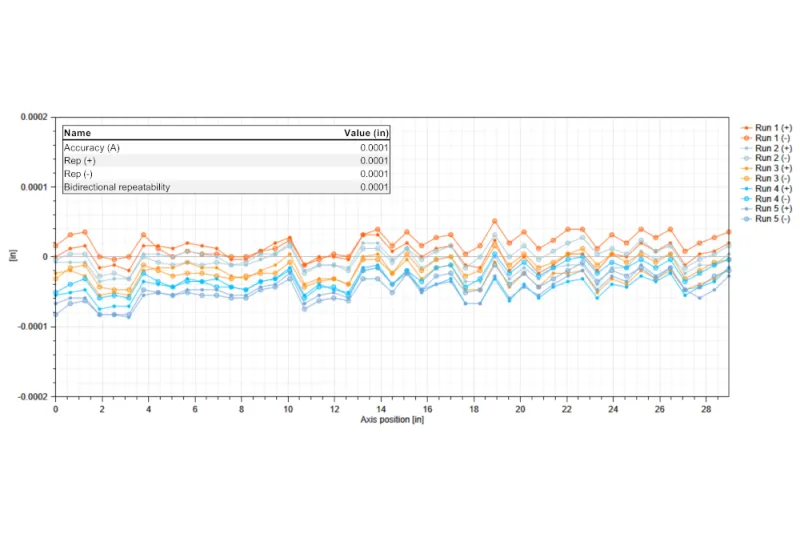

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.