The VMX650FX-WLMD 5 axis traveling bridge machine center features a table size of Ø650 mm, and a work envelope size applicable for complicated simultaneous contouring required for high accuracy machining applications. Superior +/- 3 microns machine accuracy increases profits and reduces scrap. This machine is designed to support the aerospace, medical, molding, automotive and other advanced industries.

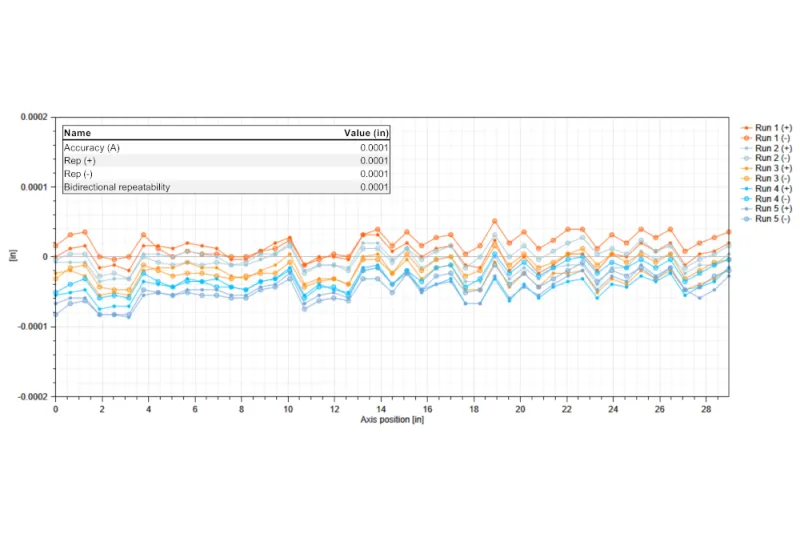

The VMX650FX series is engineered using a Traveling Column Bridge to provide rigidity, accuracy, power, and durability, in production of 3 and 5 axis machined parts. The VMX650FX series also offers the option of adding a “Pallet Pool”, improving ease of automation. The full system is controlled by a FANUC 31i-B5, features continuous motion, and produces sophisticated 5 axis parts. High Precision 35/45/45mm roller linear guides are used with robust Ø45mm pre-tensioned C2 class ball screws delivering reliable accuracy on X/Y/Z Axes. A Heidenhain rotary encoder is included on the tilting rotary axis for your most demanding applications. Dual contact #40 tool holding with two face clamping enables rigid machining and reduces tool wear. An optional HSK A63 spindle is offered, if desired.

The Hybrid 3D metal Additive-Subtractive VMX650FX prints 3D metal parts offering a choice of 10 metal material categories. The 3D metal printing process is “Powered by Meltio’s laser head” and uses wire rather than powder, making it safe to use without special protective clothing in a controlled environment, and eliminating the need for additional expensive machinery. The WLMD 3D Metal printing process eliminates most work holding fixtures, has only one machine “set up”, and allows parts to be finished within hours rather than days.

The NEW VMX650FX-WLMD is the first of its kind to provide operator control of 5 Axis CNC, 3D Metal Printing, and Robotic automation, using a single 21.5” touch screen. Matched with our QWERTY keyboard, operators can easily monitor and control operations, increasing part quality, reducing training time, and increasing SAFETY by simplifying machine operation.

➢ The WLMD process eliminates the safety hazards of powder deposition methods

➢ Reduces material costs as parts are printed to a “near net finish” (within .040”) eliminating removal of excess material, and reducing Cycle Time, labor, and power consumption costs.

➢ Eliminates costs of Work Holding fixtures & reduces Set Up time.

➢ A part can be made using two different metals, i.e. mild steel as a core metal while the outside is finished with titanium using the “Twin Wire” function.

➢ WLMD parts have fewer voids – 99.9998% denser than forgings or castings.

➢ Enables parts to be made with internal passageways for gas or liquid flow.

➢ Allows prototype parts to be made in hours rather than days or weeks.

➢ No billet needed; all parts can be printed from wire, eliminating sawing and reducing required storage.

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 25.59 | 78.74 | 118.11 |

| Y Axis | in | 32.28 | 78.74 | 157.48 | |

| Z Axis | in | 32.28 | 39.37 | 78.74 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | in | 4.92 | 0.79 | 0.79 | |

| Spindle Nose to Table Max | in | 26.57 | 40.16 | 79.53 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 2,362 | 1,575 | 1,575 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | in | --- | 78.74 | 118.11 |

| Width (Y Axis) | in | --- | 78.74 | 137.80 | |

| Diameter | in | 25.59 | --- | --- | |

| C Axis Max Workpiece Diameter | in | 25.59 | --- | --- | |

| Max Load | lb | 1,650 | 70,400 | 184,800 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 35 | 62 | 62 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | lb | 15.4 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | --- | --- | |

| Max Tool Dia. - Adj. Empty | in | 4.72 | --- | --- | |

| Max Tool Length | in | 11.81 | --- | --- | |

| DIMENSIONS | Machine Weight | lb | 22,000 | --- | --- |

| Width | in | 178 | --- | --- | |

| Depth | in | 103 | --- | --- | |

| Height | in | 138 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 650 | 2,000 | 3,000 |

| Y Axis | mm | 820 | 2,000 | 4,000 | |

| Z Axis | mm | 550 | 1,000 | 2,000 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | mm | 125 | 20 | 20 | |

| Spindle Nose to Table Max | mm | 675 | 1,020 | 2,020 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 60 | 40 | 40 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | mm | --- | 2,000 | 3,000 |

| Width (Y Axis) | mm | --- | 2,000 | 4,000 | |

| Diameter | mm | 650 | --- | --- | |

| C Axis Max Workpiece Diameter | mm | 650 | --- | --- | |

| Max Load | kg | 750 | 32,000 | 84,000 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 26 | 46 | 46 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | kg | 7 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | --- | --- | |

| Max Tool Dia. - Adj. Empty | mm | 120 | --- | --- | |

| Max Tool Length | mm | 300 | --- | --- | |

| DIMENSIONS | Machine Weight | kg | 10,000 | --- | --- |

| Width | mm | 4,500 | --- | --- | |

| Depth | mm | 2,600 | --- | --- | |

| Height | mm | 3,500 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.

Jupiter components are always chosen with long-term reliability in mind, so that you don’t need to keep reliability in your mind. New Jupiter machines come standard with a two year manufacturer’s warranty… but you won’t need it!