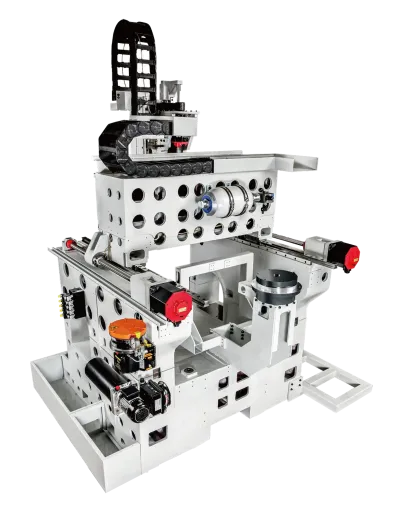

The VMX650FX 5 axis traveling column machine center features a table size of Ø650 mm, and a work envelope size applicable for complicated simultaneous contouring required for high accuracy machining applications. Superior +/- 3 microns machine accuracy increases profits and reduces scrap. This machine is designed to support the aerospace, medical, molding, automotive and other advanced industries.

The VMX650FX series is engineered using a Traveling Column to provide rigidity, accuracy, power, and durability, in production of 5 axis machined parts. The VMX650FX series also offers the options of adding a “Pallet Pool”, and Pneumatic or Hydraulic programable doors. Also available is “Through table Hydraulic or Pneumatic” clamping. For ease of automation and “Lights Out” operation all features are M-Code programable. The machine is controlled by a FANUC 31i-B5 control. Features include simultaneous X,Y, Z, A, and C motion, to produce the most sophisticated 5 axis parts. High Precision 35/45/45mm roller linear guides are matched with robust Ø45mm pre-tensioned C2 class ball screws delivering reliable accuracy on X/Y/Z Axes. A Heidenhain rotary encoder is included with the A axis tilting rotary for your most demanding applications. The Dual Contact CAT.40 spindle features tool holding with two face clamping enabling rigid machining while reducing tool wear. An optional HSK A63 spindle is also offered.

The NEW VMX650FX has a 21.5” touch screen monitor, our backlit Jupiter control panel, and features our QWERTY keyboard. Operators can easily monitor and control operations, increasing part quality, reducing training time, and increasing SAFETY by simplifying machine operation.

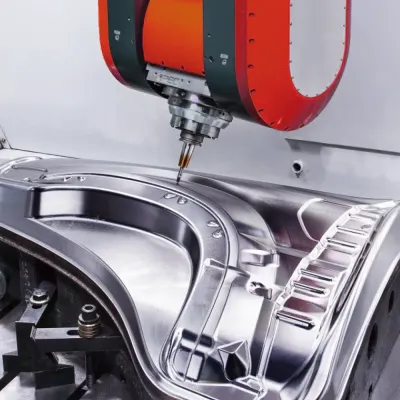

Jupiter’s Hurricane platform provides simultaneous 5-axis mold-making quality machining performance at a fraction of the price demanded by European competitors. Each machine is tailor-made to your exact requirements and subject to extremely rigorous performance testing before it ever leaves the factory. Hold the impeller test part in your hands before your new Hurricane arrives!

For larger workpieces upgrade to our high speed Maglev gantry platform. Push mold-making performance to the very limit with silky smooth 30,000 rpm HSK spindles, blisteringly fast maglev linear motor drives, and Heidenhain glass scales and encoders!

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 25.59 | 78.74 | 118.11 |

| Y Axis | in | 32.28 | 78.74 | 157.48 | |

| Z Axis | in | 32.28 | 39.37 | 78.74 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | in | 4.92 | 0.79 | 0.79 | |

| Spindle Nose to Table Max | in | 26.57 | 40.16 | 79.53 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 2,362 | 1,575 | 1,575 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | in | --- | 78.74 | 118.11 |

| Width (Y Axis) | in | --- | 78.74 | 137.80 | |

| Diameter | in | 25.59 | --- | --- | |

| C Axis Max Workpiece Diameter | in | 25.59 | --- | --- | |

| Max Load | lb | 1,650 | 70,400 | 184,800 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 35 | 62 | 62 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | lb | 15.4 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | --- | --- | |

| Max Tool Dia. - Adj. Empty | in | 4.72 | --- | --- | |

| Max Tool Length | in | 11.81 | --- | --- | |

| DIMENSIONS | Machine Weight | lb | 22,000 | --- | --- |

| Width | in | 178 | --- | --- | |

| Depth | in | 103 | --- | --- | |

| Height | in | 138 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 650 | 2,000 | 3,000 |

| Y Axis | mm | 820 | 2,000 | 4,000 | |

| Z Axis | mm | 550 | 1,000 | 2,000 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | mm | 125 | 20 | 20 | |

| Spindle Nose to Table Max | mm | 675 | 1,020 | 2,020 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 60 | 40 | 40 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | mm | --- | 2,000 | 3,000 |

| Width (Y Axis) | mm | --- | 2,000 | 4,000 | |

| Diameter | mm | 650 | --- | --- | |

| C Axis Max Workpiece Diameter | mm | 650 | --- | --- | |

| Max Load | kg | 750 | 32,000 | 84,000 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 26 | 46 | 46 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | kg | 7 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | --- | --- | |

| Max Tool Dia. - Adj. Empty | mm | 120 | --- | --- | |

| Max Tool Length | mm | 300 | --- | --- | |

| DIMENSIONS | Machine Weight | kg | 10,000 | --- | --- |

| Width | mm | 4,500 | --- | --- | |

| Depth | mm | 2,600 | --- | --- | |

| Height | mm | 3,500 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

Jupiter partners with the world’s leading CNC system providers to deliver whatever platform you prefer.

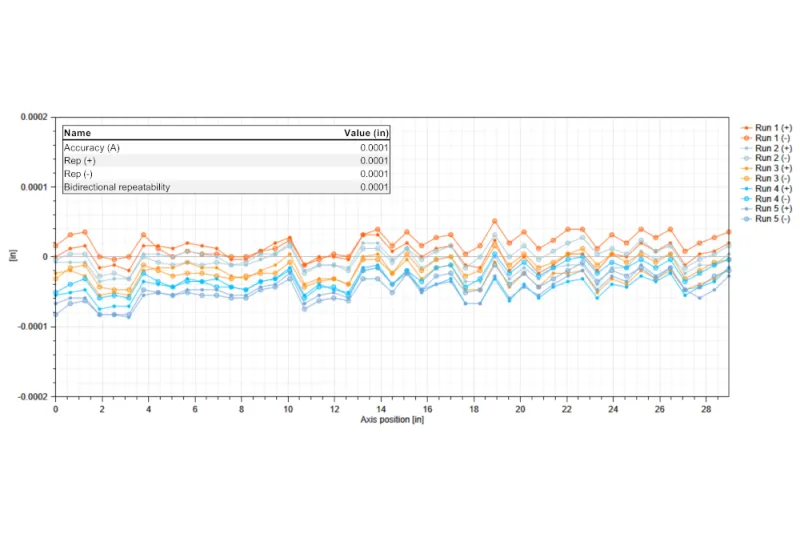

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.