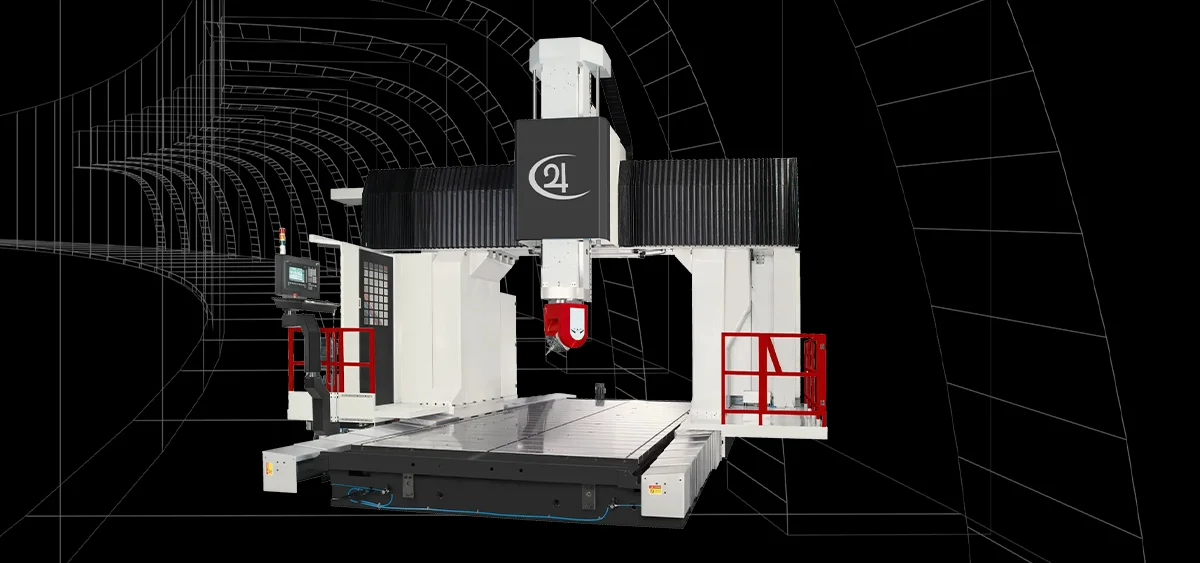

For the largest, heaviest 3 to 5 axis parts look no further than a Jupiter bridge or gantry mill. The bridge and gantry lines come in a wide array of sizes and each mill is custom built to your unique application needs. 3 axis, 5 face, and full 5 axis simultaneous configurations are all available. Want to install a massive rotary on the table for long cylindrical parts? We can do that too!

| SPECIFICATIONS | UNIT | BRIDGE MIN | BRIDGE MAX | |

|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 86.61 | 244.09 |

| Y Axis | in | 59.06 | 118.11 | |

| Z Axis | in | 29.92 | 39.37 | |

| Spindle Nose to Table Min | in | 4.53 | 4.92 | |

| Spindle Nose to Table Max | in | 35.04 | 46.26 | |

| Distance Between Columns | in | 59.06 | 118.11 | |

| MOTION | Way Type - X Axis | --- | Roller Guide | Roller Guide |

| Way Type - Y Axis | --- | Roller Guide | Roller Guide | |

| Way Type - Z Axis | --- | Hardened Box Way | Hardened Box Way | |

| Rapid Traverse - X Axis | ipm | 787 | 472 | |

| Rapid Traverse - Y Axis | ipm | 787 | 591 | |

| Rapid Traverse - Z Axis | ipm | 591 | 394 | |

| TABLE | Length (X Axis) | in | 78.74 | 236.22 |

| Width (Y Axis) | in | 47.24 | 98.43 | |

| Max Load | lb | 8,800 | 55,000 | |

| SPINDLE | Configuration | --- | Multiple styles based on application need | |

| ATC | Capacity | Tools | 40 | 40 |

| Max Tool Weight | lb | 44 | 44 | |

| Max Tool Dia. - Adj. Occupied | in | 4.92 | 4.92 | |

| Max Tool Dia. - Adj. Empty | in | 8.46 | 8.46 | |

| Max Tool Length | in | 13.78 | 15.75 | |

| DIMENSIONS | Machine Weight | lb | 28,600 | 125,400 |

| Length (X Axis) | in | 246 | 591 | |

| Width (Y Axis) | in | 175 | 235 | |

| Height | in | 157 | 207 | |

| SPECIFICATIONS | UNIT | GANTRY MIN | GANTRY MAX | |

|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 2,200 | 6,200 |

| Y Axis | mm | 1,500 | 3,000 | |

| Z Axis | mm | 760 | 1,000 | |

| Spindle Nose to Table Min | mm | 115 | 125 | |

| Spindle Nose to Table Max | mm | 890 | 1,175 | |

| Distance Between Columns | mm | 1,500 | 3,000 | |

| MOTION | Way Type - X Axis | --- | Roller Guide | Roller Guide |

| Way Type - Y Axis | --- | Roller Guide | Roller Guide | |

| Way Type - Z Axis | --- | Hardened Box Way | Hardened Box Way | |

| Rapid Traverse - X Axis | m/min | 20 | 12 | |

| Rapid Traverse - Y Axis | m/min | 20 | 15 | |

| Rapid Traverse - Z Axis | m/min | 15 | 10 | |

| TABLE | Length (X Axis) | mm | 2,000 | 6,000 |

| Width (Y Axis) | mm | 1,200 | 2,500 | |

| Max Load | kg | 4,000 | 25,000 | |

| SPINDLE | Configuration | --- | Multiple styles based on application need | |

| ATC | Capacity | Tools | 40 | 40 |

| Max Tool Weight | kg | 20 | 20 | |

| Max Tool Dia. - Adj. Occupied | mm | 125 | 125 | |

| Max Tool Dia. - Adj. Empty | mm | 215 | 215 | |

| Max Tool Length | mm | 400 | 400 | |

| DIMENSIONS | Machine Weight | kg | 13,000 | 57,000 |

| Length (X Axis) | mm | 6,230 | 15,000 | |

| Width (Y Axis) | mm | 4,430 | 5,950 | |

| Height | mm | 4,000 | 5,250 | |

| SPECIFICATIONS | UNIT | GANTRY MIN | GANTRY MAX | |

|---|---|---|---|---|

| CNC SYSTEM | Control | — | Fanuc 31i | Fanuc 31i |

| Configuration | — | 15″ Touchpanel | 15″ Touchpanel | |

| Motors & Amps | — | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 125.98 | 322.83 |

| Y Axis | in | 106.30 | 165.35 | |

| Z Axis | in | 39.37 | 39.37 | |

| Spindle Nose to Table Min | in | 7.87 | 7.87 | |

| Spindle Nose to Table Max | in | 47.24 | 47.24 | |

| Distance Between Columns | in | 78.74 | 137.80 | |

| MOTION | Way Type – X Axis | — | Roller Guide | Roller Guide |

| Way Type – Y Axis | — | Roller Guide | Roller Guide | |

| Way Type – Z Axis | — | Hardened Box Way | Hardened Box Way | |

| Rapid Traverse – X Axis | ipm | 519 | 394 | |

| Rapid Traverse – Y Axis | ipm | 591 | 472 | |

| Rapid Traverse – Z Axis | ipm | 394 | 394 | |

| TABLE | Length (X Axis) | in | 118.11 | 314.96 |

| Width (Y Axis) | in | 62.99 | 118.11 | |

| Max Load | lb | 22,000 | 77,000 | |

| SPINDLE | Configuration | — | Multiple styles based on application need | |

| ATC | Capacity | Tools | 60 | 60 |

| Max Tool Weight | lb | 44 | 44 | |

| Max Tool Dia. – Adj. Occupied | in | 4.92 | 4.92 | |

| Max Tool Dia. – Adj. Empty | in | 8.46 | 8.46 | |

| Max Tool Length | in | 15.75 | 15.75 | |

| DIMENSIONS | Machine Weight | lb | 66,000 | 171,600 |

| Length (X Axis) | in | 327 | 788 | |

| Width (Y Axis) | in | 233 | 296 | |

| Height | in | 213 | 221 | |

| SPECIFICATIONS | UNIT | GANTRY MIN | GANTRY MAX | |

|---|---|---|---|---|

| CNC SYSTEM | Control | — | Fanuc 31i | Fanuc 31i |

| Configuration | — | 15″ Touchpanel | 15″ Touchpanel | |

| Motors & Amps | — | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 3,200 | 8,200 |

| Y Axis | mm | 2,700 | 4,200 | |

| Z Axis | mm | 1,000 | 1,000 | |

| Spindle Nose to Table Min | mm | 200 | 200 | |

| Spindle Nose to Table Max | mm | 1,200 | 1,200 | |

| Distance Between Columns | mm | 2,000 | 3,500 | |

| MOTION | Way Type – X Axis | — | Roller Guide | Roller Guide |

| Way Type – Y Axis | — | Roller Guide | Roller Guide | |

| Way Type – Z Axis | — | Hardened Box Way | Hardened Box Way | |

| Rapid Traverse – X Axis | m/min | 15 | 10 | |

| Rapid Traverse – Y Axis | m/min | 15 | 12 | |

| Rapid Traverse – Z Axis | m/min | 10 | 10 | |

| TABLE | Length (X Axis) | mm | 3,000 | 8,000 |

| Width (Y Axis) | mm | 1,600 | 3,000 | |

| Max Load | kg | 10,000 | 35,000 | |

| SPINDLE | Configuration | — | Multiple styles based on application need | |

| ATC | Capacity | Tools | 60 | 60 |

| Max Tool Weight | kg | 20 | 20 | |

| Max Tool Dia. – Adj. Occupied | mm | 125 | 125 | |

| Max Tool Dia. – Adj. Empty | mm | 215 | 215 | |

| Max Tool Length | mm | 400 | 400 | |

| DIMENSIONS | Machine Weight | kg | 30,000 | 78,000 |

| Length (X Axis) | mm | 8,300 | 20,000 | |

| Width (Y Axis) | mm | 5,900 | 7,500 | |

| Height | mm | 5,400 | 5,600 | |

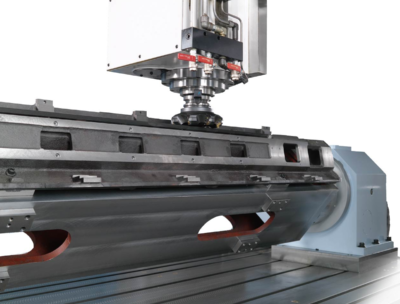

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.