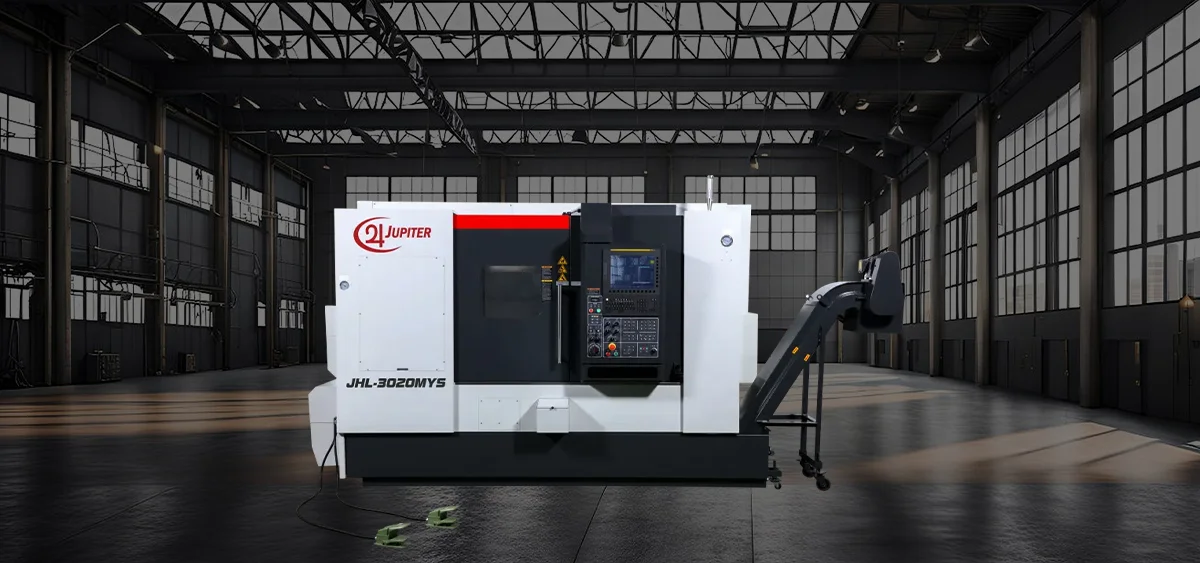

The humble CNC lathe is the unsung hero of every machine shop. While the 5 axis machines get all the glory and attention front and center, the lathe sits in the corner turning part after part to keep the lights on in between marquee jobs. Jupiter’s multi-function lathe line is built to serve you quietly and competently for years and years. Each lathe features an extra-heavy Meehanite casting for vibration absorption, box ways for handling the highest cutting forces, and precision balanced spindles to turn the most perfect cylinders.

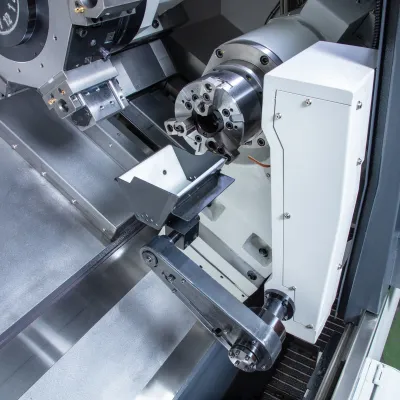

When the customer needs more complex parts, step up to an MY or MYS configuration and enjoy Sauter BMT-60 live tooling at 6,000 RPM combined with a sub-spindle and 6″ chuck for turning and milling both ends of your part.

| SPECIFICATIONS | UNIT | JHL-2016 | JHL-3024 | JHL-3042 | JHL-3020MY | JHL-3020MYS | |

|---|---|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | Alpha Class | Alpha Class | |

| CAPACITY | Swing Over Bed | in | 21.65 | 25.75 | 23.23 | 23.62 | 23.62 |

| Swing Over Saddle | in | 12.99 | 16.46 | 14.96 | 23.62 | 23.62 | |

| Max Turning Diameter | in | 11.81 | 20.08 | 17.72 | 18.11 | 18.11 | |

| Max Working Length | in | 17.44 | 23.39 | 39.37 | 21.57 | 21.57 | |

| Distance Between Centers | in | 19.96 | 29.45 | 46.46 | 30.71 | 28.15 | |

| Bar Capacity | in ⌀ | 2.05 | 3.03 | 3.15 | 3.03 | 3.03 | |

| Sub-Spindle Bar Capacity | in ⌀ | --- | --- | --- | --- | 2.05 | |

| Chuck Size | in | 8 | 10 | 10 | 10 | 10 | |

| Sub-Spindle Chuck Size | in ⌀ | --- | --- | --- | --- | 6 | |

| STROKE | X Axis | in | 8.27 | 11.42 | 9.65 | 12.20 | 12.20 |

| Y Axis | in | --- | --- | --- | ± 2.17 | ± 2.17 | |

| Z Axis | in | 17.72 | 25.20 | 43.31 | 24.41 | 24.41 | |

| FEEDRATE | X Axis | ipm | 787 | 787 | 630 | 787 | 787 |

| Y Axis | ipm | --- | --- | --- | 787 | 787 | |

| Z Axis | ipm | 787 | 787 | 787 | 787 | 787 | |

| SPINDLE | Speed | rpm | 4,000 | 2,500 | 2,500 | 3,500 | 3,500 |

| Nose | --- | A2-6 | A2-8 | A2-8 | A2-8 | A2-8 | |

| Bore | in | 2.44 | 3.46 | 3.58 | 3.46 | 3.46 | |

| SUB-SPINDLE | Speed | rpm | --- | --- | --- | --- | 6,000 |

| Nose | --- | --- | --- | --- | --- | A2-5 | |

| Bore | in | --- | --- | --- | --- | 2.56 | |

| TURRET | Turret Type | --- | Servo | Servo | Servo | Sauter BMT-60 | Sauter BMT-60 |

| Stations | --- | 12 | 12 | 10 | 12 | 12 | |

| Square Tool Dimension | in | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |

| Boring Tool Dimensions | in ⌀ | 1.50 | 1.50 | 1.50 | 1.50 | 1.50 | |

| Indexing Time | s, T-T | 0.2 | 0.2 | 0.5 | 0.2 | 0.2 | |

| Live Tool Spindle Speed | rpm | --- | --- | --- | 6,000 | 6,000 | |

| Live Tool Motor Power | hp | --- | --- | --- | 6.0 | 6.0 | |

| TAILSTOCK | Movement Type | --- | Manual | Manual | Programmable | Servo | -- |

| Body Stroke | in | 12.20 | 21.65 | 39.37 | 25.59 | --- | |

| Quill Movement Type | --- | Hydraulic | Hydraulic | Hydraulic | --- | --- | |

| Quill Stroke | in | 4.72 | 5.12 | 3.94 | --- | --- | |

| Quill Diameter | in | 2.95 | 3.54 | 4.41 | --- | --- | |

| Quill Taper | -- | MT5 | MT5 | MT4 | --- | --- | |

| MOTOR | Motor Power | hp | 20.1 | 24.8 | 33.5 | 20.1 | 20.1 |

| Sub-Spindle Motor Power | hp | --- | --- | --- | --- | 10.1 | |

| Axial Servo Motor - X | hp | 3.4 | 4.0 | 2.4 | 3.6 | 3.6 | |

| Axial Servo Motor - Y | hp | --- | --- | --- | 3.6 | 3.6 | |

| Axial Servo Motor - Z | hp | 3.4 | 4.0 | 3.4 | 3.6 | 3.6 | |

| DIMENSIONS | Machine Weight | lb | 7,700 | 12,760 | 12,100 | 18,150 | 18,370 |

| Width | in | 141 | 169 | 171 | 172 | 172 | |

| Depth | in | 64 | 76 | 71 | 75 | 75 | |

| Height | in | 67 | 77 | 76 | 84 | 84 | |

| Power | kVA | 20 | 30 | 30 | 40 | 40 | |

| SPECIFICATIONS | UNIT | JHL-3020MY | JHL-3020MYS | |

|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-TF+ | Fanuc 0i-TF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | |

| CAPACITY | Swing Over Bed | in | 23.62 | 23.62 |

| Swing Over Saddle | in | 23.62 | 23.62 | |

| Max Turning Diameter | in | 18.11 | 18.11 | |

| Max Working Length | in | 21.57 | 21.57 | |

| Distance Between Centers | in | 30.71 | 28.15 | |

| Bar Capacity | in ⌀ | 3.03 | 3.03 | |

| Sub-Spindle Bar Capacity | in ⌀ | --- | 2.05 | |

| Chuck Size | in | 10 | 10 | |

| Sub-Spindle Chuck Size | in ⌀ | --- | 6 | |

| STROKE | X Axis | in | 12.20 | 12.20 |

| Y Axis | in | ± 2.17 | ± 2.17 | |

| Z Axis | in | 24.41 | 24.41 | |

| FEEDRATE | X Axis | ipm | 787 | 787 |

| Y Axis | ipm | 787 | 787 | |

| Z Axis | ipm | 787 | 787 | |

| SPINDLE | Speed | rpm | 3,500 | 3,500 |

| Nose | --- | A2-8 | A2-8 | |

| Bore | in | 3.46 | 3.46 | |

| SUB-SPINDLE | Speed | rpm | --- | 6,000 |

| Nose | --- | --- | A2-5 | |

| Bore | in | --- | 2.56 | |

| TURRET | Turret Type | --- | Sauter BMT-60 | Sauter BMT-60 |

| Stations | --- | 12 | 12 | |

| Square Tool Dimension | in | 1.00 | 1.00 | |

| Boring Tool Dimensions | in ⌀ | 1.50 | 1.50 | |

| Indexing Time | s, T-T | 0.2 | 0.2 | |

| Live Tool Spindle Speed | rpm | 6,000 | 6,000 | |

| Live Tool Motor Power | hp | 6.0 | 6.0 | |

| TAILSTOCK | Movement Type | --- | Servo | -- |

| Body Stroke | in | 25.59 | --- | |

| Quill Movement Type | --- | --- | --- | |

| Quill Stroke | in | --- | --- | |

| Quill Diameter | in | --- | --- | |

| Quill Taper | -- | --- | --- | |

| MOTOR | Motor Power | hp | 20.1 | 20.1 |

| Sub-Spindle Motor Power | hp | --- | 10.1 | |

| Axial Servo Motor - X | hp | 3.6 | 3.6 | |

| Axial Servo Motor - Y | hp | 3.6 | 3.6 | |

| Axial Servo Motor - Z | hp | 3.6 | 3.6 | |

| DIMENSIONS | Machine Weight | lb | 18,150 | 18,370 |

| Width | in | 172 | 172 | |

| Depth | in | 75 | 75 | |

| Height | in | 84 | 84 | |

| Power | kVA | 40 | 40 | |

| SPECIFICATIONS | UNIT | JHL-2016 | JHL-3024 | JHL-3042 | JHL-3020MY | JHL-3020MYS | |

|---|---|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ | Fanuc 0i-TF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | Alpha Class | Alpha Class | |

| CAPACITY | Swing Over Bed | mm | 550 | 654 | 590 | 600 | 600 |

| Swing Over Saddle | mm | 330 | 418 | 380 | 600 | 600 | |

| Max Turning Diameter | mm | 300 | 510 | 450 | 460 | 460 | |

| Max Working Length | mm | 443 | 594 | 1,000 | 548 | 548 | |

| Distance Between Centers | mm | 507 | 748 | 1,180 | 780 | 715 | |

| Bar Capacity | mm ⌀ | 52 | 77 | 80 | 77 | 77 | |

| Sub-Spindle Bar Capacity | mm ⌀ | --- | --- | --- | --- | 52 | |

| Chuck Size | in | 8 | 10 | 10 | 10 | 10 | |

| Sub-Spindle Chuck Size | in ⌀ | --- | --- | --- | --- | 6 | |

| STROKE | X Axis | mm | 210 | 290 | 245 | 310 | 310 |

| Y Axis | mm | --- | --- | --- | ± 55 | ± 55 | |

| Z Axis | mm | 450 | 640 | 1,100 | 620 | 620 | |

| FEEDRATE | X Axis | m/min | 20 | 20 | 16 | 20 | 20 |

| Y Axis | m/min | --- | --- | --- | 20 | 20 | |

| Z Axis | m/min | 20 | 20 | 20 | 20 | 20 | |

| SPINDLE | Speed | rpm | 4,000 | 2,500 | 2,500 | 3,500 | 3,500 |

| Nose | --- | A2-6 | A2-8 | A2-8 | A2-8 | A2-8 | |

| Bore | mm | 62 | 88 | 91 | 88 | 88 | |

| SUB-SPINDLE | Speed | rpm | --- | --- | --- | --- | 6,000 |

| Nose | --- | --- | --- | --- | --- | A2-5 | |

| Bore | mm | --- | --- | --- | --- | 65 | |

| TURRET | Turret Type | --- | Servo | Servo | Servo | Sauter BMT-60 | Sauter BMT-60 |

| Stations | --- | 12 | 12 | 10 | 12 | 12 | |

| Square Tool Dimension | mm | 25 | 25 | 25 | 25 | 25 | |

| Boring Tool Dimensions | mm ⌀ | 40 | 40 | 40 | 40 | 40 | |

| Indexing Time | s, T-T | 0.2 | 0.2 | 0.5 | 0.2 | 0.2 | |

| Live Tool Spindle Speed | rpm | --- | --- | --- | 6,000 | 6,000 | |

| Live Tool Motor Power | kW | --- | --- | --- | 4.5 | 4.5 | |

| TAILSTOCK | Movement Type | --- | Manual | Manual | Programmable | Servo | -- |

| Body Stroke | mm | 310 | 550 | 1,000 | 650 | --- | |

| Quill Movement Type | --- | Hydraulic | Hydraulic | Hydraulic | --- | --- | |

| Quill Stroke | mm | 120 | 130 | 100 | --- | --- | |

| Quill Diameter | mm | 75 | 90 | 112 | --- | --- | |

| Quill Taper | -- | MT5 | MT5 | MT4 | --- | --- | |

| MOTOR | Motor Power | kW | 15 | 18.5 | 25 | 15 | 15 |

| Sub-Spindle Motor Power | kW | --- | --- | --- | --- | 7.5 | |

| Axial Servo Motor - X | kW | 2.5 | 3.0 | 1.8 | 2.7 | 2.7 | |

| Axial Servo Motor - Y | kW | --- | --- | --- | 2.7 | 2.7 | |

| Axial Servo Motor - Z | kW | 2.5 | 3.0 | 2.5 | 2.7 | 2.7 | |

| DIMENSIONS | Machine Weight | kg | 3,500 | 5,800 | 5,500 | 8,250 | 8,350 |

| Width | mm | 3,600 | 4,300 | 4,400 | 4,400 | 4,400 | |

| Depth | mm | 1,700 | 2,000 | 1,800 | 1,900 | 1,900 | |

| Height | mm | 1,700 | 2,000 | 2,000 | 2,150 | 2,150 | |

| Power | kVA | 20 | 30 | 30 | 40 | 40 | |

| SPECIFICATIONS | UNIT | JHL-3020MY | JHL-3020MYS | |

|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-TF+ | Fanuc 0i-TF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | |

| CAPACITY | Swing Over Bed | mm | 600 | 600 |

| Swing Over Saddle | mm | 600 | 600 | |

| Max Turning Diameter | mm | 460 | 460 | |

| Max Working Length | mm | 548 | 548 | |

| Distance Between Centers | mm | 780 | 715 | |

| Bar Capacity | mm ⌀ | 77 | 77 | |

| Sub-Spindle Bar Capacity | mm ⌀ | --- | 52 | |

| Chuck Size | in | 10 | 10 | |

| Sub-Spindle Chuck Size | in ⌀ | --- | 6 | |

| STROKE | X Axis | mm | 310 | 310 |

| Y Axis | mm | ± 55 | ± 55 | |

| Z Axis | mm | 620 | 620 | |

| FEEDRATE | X Axis | m/min | 20 | 20 |

| Y Axis | m/min | 20 | 20 | |

| Z Axis | m/min | 20 | 20 | |

| SPINDLE | Speed | rpm | 3,500 | 3,500 |

| Nose | --- | A2-8 | A2-8 | |

| Bore | mm | 88 | 88 | |

| SUB-SPINDLE | Speed | rpm | --- | 6,000 |

| Nose | --- | --- | A2-5 | |

| Bore | mm | --- | 65 | |

| TURRET | Turret Type | --- | Sauter BMT-60 | Sauter BMT-60 |

| Stations | --- | 12 | 12 | |

| Square Tool Dimension | mm | 25 | 25 | |

| Boring Tool Dimensions | mm ⌀ | 40 | 40 | |

| Indexing Time | s, T-T | 0.2 | 0.2 | |

| Live Tool Spindle Speed | rpm | 6,000 | 6,000 | |

| Live Tool Motor Power | kW | 4.5 | 4.5 | |

| TAILSTOCK | Movement Type | --- | Servo | -- |

| Body Stroke | mm | 650 | --- | |

| Quill Movement Type | --- | --- | --- | |

| Quill Stroke | mm | --- | --- | |

| Quill Diameter | mm | --- | --- | |

| Quill Taper | -- | --- | --- | |

| MOTOR | Motor Power | kW | 15 | 15 |

| Sub-Spindle Motor Power | kW | --- | 7.5 | |

| Axial Servo Motor - X | kW | 2.7 | 2.7 | |

| Axial Servo Motor - Y | kW | 2.7 | 2.7 | |

| Axial Servo Motor - Z | kW | 2.7 | 2.7 | |

| DIMENSIONS | Machine Weight | kg | 8,250 | 8,350 |

| Width | mm | 4,400 | 4,400 | |

| Depth | mm | 1,900 | 1,900 | |

| Height | mm | 2,150 | 2,150 | |

| Power | kVA | 40 | 40 | |

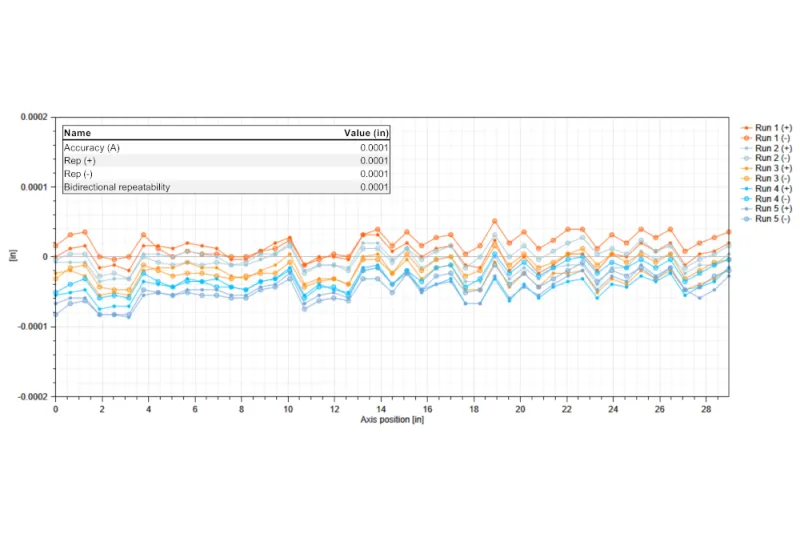

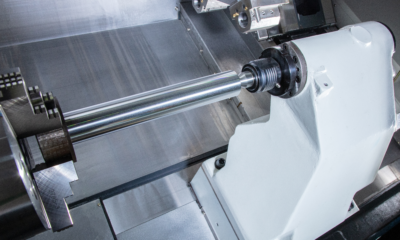

Each axis is driven by high precision C2 class ballscrews. All ballscrews are centered between the guide ways. Linear axes have 4/4/6 trucks for maximum rigidity. Ballscrews are pretensioned and supported at each end with angular contact thrust bearings. All axes are connected directly to digital servo drive motors for immediate response and accuracy.