With a 5 axis CNC machining, you can reduce setup time and increase accuracy on each part.

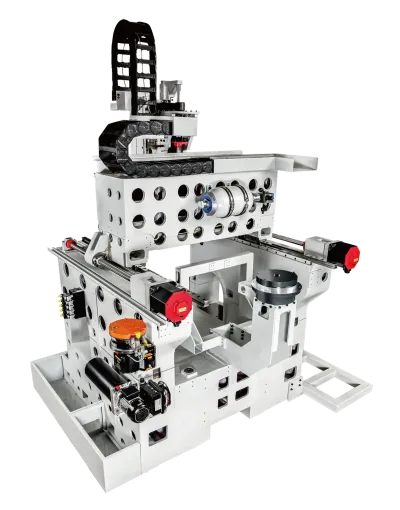

Jupiter’s 5-axis universal CNC machining centers come in both trunnion and gantry configuration. All models are form factor optimized to provide tremendous machining volume to floor-space ratios. From the castings to the spindle bearings, Jupiter selects only the highest quality components to guarantee many years of flawless mold-making, aerospace, automotive, and other parts.

Jupiter’s Hurricane platform provides simultaneous 5-axis mold-making quality machining performance at a fraction of the price demanded by European competitors. Each machine is tailor-made to your exact requirements and subject to extremely rigorous performance testing before it ever leaves the factory. Hold the impeller test part in your hands before your new Hurricane arrives!

For larger workpieces upgrade to our high speed Maglev gantry platform. Push mold-making performance to the very limit with silky smooth 30,000 rpm HSK spindles, blisteringly fast maglev linear motor drives, and Heidenhain glass scales and encoders!

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 25.59 | 78.74 | 118.11 |

| Y Axis | in | 32.28 | 78.74 | 157.48 | |

| Z Axis | in | 32.28 | 39.37 | 78.74 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | in | 4.92 | 0.79 | 0.79 | |

| Spindle Nose to Table Max | in | 26.57 | 40.16 | 79.53 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 2,362 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 2,362 | 1,575 | 1,575 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | in | --- | 78.74 | 118.11 |

| Width (Y Axis) | in | --- | 78.74 | 137.80 | |

| Diameter | in | 25.59 | --- | --- | |

| C Axis Max Workpiece Diameter | in | 25.59 | --- | --- | |

| Max Load | lb | 1,650 | 70,400 | 184,800 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 35 | 62 | 62 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | lb | 15.4 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | --- | --- | |

| Max Tool Dia. - Adj. Empty | in | 4.72 | --- | --- | |

| Max Tool Length | in | 11.81 | --- | --- | |

| DIMENSIONS | Machine Weight | lb | 22,000 | --- | --- |

| Width | in | 178 | --- | --- | |

| Depth | in | 103 | --- | --- | |

| Height | in | 138 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

| SPECIFICATIONS | UNIT | HURRICANE 650 | MAGLEV 2020 | MAGLEV 3040 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 31i | Fanuc 31i | Fanuc 31i |

| Configuration | --- | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | 15" Touchpanel w/ Axiset | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 650 | 2,000 | 3,000 |

| Y Axis | mm | 820 | 2,000 | 4,000 | |

| Z Axis | mm | 550 | 1,000 | 2,000 | |

| A Axis | deg | +100˚ ~ -120˚ | ± 105˚ | ± 105˚ | |

| C Axis | deg | 360˚ | ± 200˚ | ± 200˚ | |

| Spindle Nose to Table Min | mm | 125 | 20 | 20 | |

| Spindle Nose to Table Max | mm | 675 | 1,020 | 2,020 | |

| MOTION | Way Type | --- | Roller Linear | Maglev (Linear Motor) | Maglev (Linear Motor) |

| Rapid Traverse - X Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 60 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 60 | 40 | 40 | |

| A Axis Max Speed | rpm | 5 | --- | --- | |

| C Axis Max Speed | rpm | 300 | --- | --- | |

| TABLE | Length (X Axis) | mm | --- | 2,000 | 3,000 |

| Width (Y Axis) | mm | --- | 2,000 | 4,000 | |

| Diameter | mm | 650 | --- | --- | |

| C Axis Max Workpiece Diameter | mm | 650 | --- | --- | |

| Max Load | kg | 750 | 32,000 | 84,000 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 26 | 46 | 46 | |

| Taper | --- | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A63 | HSK-A100 | |

| Speed | rpm | 15,000 | 15,000 to 30,000 | 15,000 to 30,000 | |

| Optional Speed | rpm | 20,000 | various | various | |

| ATC | Capacity | Tools | 60 | 24 | 24 |

| Max Tool Weight | kg | 7 | --- | --- | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | --- | --- | |

| Max Tool Dia. - Adj. Empty | mm | 120 | --- | --- | |

| Max Tool Length | mm | 300 | --- | --- | |

| DIMENSIONS | Machine Weight | kg | 10,000 | --- | --- |

| Width | mm | 4,500 | --- | --- | |

| Depth | mm | 2,600 | --- | --- | |

| Height | mm | 3,500 | --- | --- | |

| Current | kVA | 45 | --- | --- | |

Jupiter partners with the world’s leading CNC system providers to deliver whatever platform you prefer.