The JUPITER VMC-6330 Vertical Machining Center is a high performance, premium machine tool, designed to feature maximum capacity and performance in many demanding industries. The compact footprint, yet powerful platform satisfies Mold & Die, Medical, Aerospace, Automotive and many other critical applications.

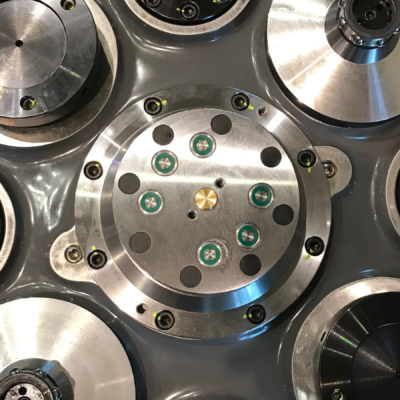

The VMC series is engineered in a unique wide column design for an excellent foundation. High Precision 45/55/45mm roller linear guides are used with robust Ø50mm pre-tensioned C2 class ball screw for reliable accuracy on X/Y/Z Axes. Standard chain type 48 tool ATC with max tool diameters of 75mm/150mm, with/without adjacent tools. Features a high precision BBT40 spindle with two face clamping for rigid machining and reduced tool wear.

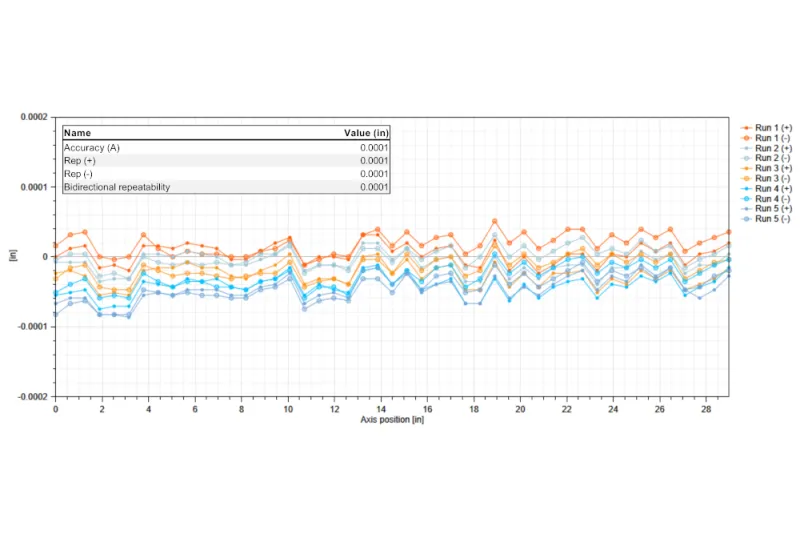

Our artisans still perform precision hand scraping of each section for precise alignment resulting in positioning accuracy of .0002” (.006mm) and repeatability of .00015”(.004mm).

Automatic thermal cooling is an available option for spindle, headstock, ball screws and motors to achieve consistent high accuracy with maximum reliability.

The printed parts are very similar to forged parts but has higher densification, virtually eliminating voids and porosity, does not have a grain like billet material making it stronger, and parts are unlimited in shape. The work/print part envelope is 36” X 20” X 20”.

➢ The WLMD process eliminates the safety hazards of powder deposition methods

➢ Reduces material costs as parts are printed to a “near net finish” (within .040”)

eliminating removal of excess material, and reducing Cycle Time, labor, and

power consumption costs.

➢ Eliminates costs of Work Holding fixtures & reduces Set Up time.

➢ A part can be made using two different metals, i.e. mild steel as a core metal

while the outside is finished with titanium using the “Twin Wire” function.

➢ WLMD parts have fewer voids – 99.9998% denser than forgings or castings.

➢ Enables parts to be made with internal passageways for gas or liquid flow.

➢ Allows prototype parts to be made in hours rather than days or weeks.

➢ No billet needed; all parts can be printed from wire, eliminating sawing and

reducing required storage.

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | in | 19.69 | 23.62 | 31.50 |

| Y Axis | in | 16.54 | 19.69 | 31.50 | |

| Z Axis | in | 14.96 | 19.69 | 31.50 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Y Axis | ipm | 1,890 | 2,362 | 2,362 | |

| Rapid Traverse - Z Axis | ipm | 1,890 | 2,362 | 2,362 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | in | 14.96 | 15.75 | 19.69 | |

| Depth | in | 14.96 | 15.75 | 19.69 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | lb | 440 | 880 | 1,320 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | hp | 30 | 30 | 30 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | lb | 15.4 | 15.4 | 24.2 | |

| Max Tool Dia. - Adj. Occupied | in | 3.15 | 2.95 | 3.74 | |

| Max Tool Dia. - Adj. Empty | in | 4.92 | 4.92 | 7.87 | |

| Max Tool Length | in | 9.84 | 11.81 | 15.75 | |

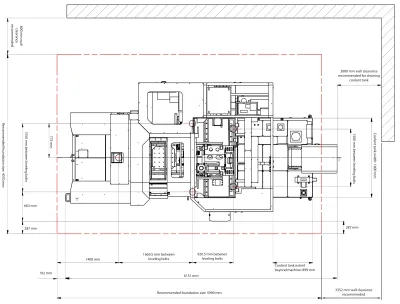

| DIMENSIONS | Machine Weight | lb | 7,700 | 12,100 | 29,700 |

| Width | in | 59 | 96 | 122 | |

| Depth | in | 99 | 141 | 240 | |

| Height | in | 97 | 108 | 119 | |

| Current | kVA | 30 | 40 | 45 | |

| SPECIFICATIONS | UNIT | HMC-380 | HMC-400 | HMC-500 | |

|---|---|---|---|---|---|

| CNC SYSTEM | Control | --- | Fanuc 0i-MF+ | Fanuc 0i-MF+ | Fanuc 0i-MF+ |

| Configuration | --- | 15" Touchpanel | 15" Touchpanel | 15" Touchpanel | |

| Motors & Amps | --- | Alpha Class | Alpha Class | Alpha Class | |

| TRAVEL | X Axis | mm | 500 | 600 | 800 |

| Y Axis | mm | 420 | 500 | 800 | |

| Z Axis | mm | 380 | 500 | 800 | |

| MOTION | Way Type | --- | Roller Linear | Roller Linear | Roller Linear |

| Rapid Traverse - X Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Y Axis | m/min | 48 | 60 | 60 | |

| Rapid Traverse - Z Axis | m/min | 48 | 60 | 60 | |

| PALLET | Pallet Count | --- | 1 | 2 | 2 |

| Width | mm | 380 | 400 | 500 | |

| Depth | mm | 380 | 400 | 500 | |

| Minimum Index | deg | 0.001 | 0.001 | 0.001 | |

| Max Load Per Pallet | kg | 200 | 400 | 600 | |

| SPINDLE | Drive Type | --- | Built-in | Built-in | Built-in |

| Motor Power | kW | 22 | 22 | 22 | |

| Taper | --- | CAT-40 DC | CAT-40 DC | CAT-40 DC | |

| Speed | rpm | 12,000 | 12,000 | 12,000 | |

| Optional Speed | rpm | 15,000 | 15,000 | 15,000 | |

| ATC | Capacity | Tools | 24 | 40 (60) | 40 (80) |

| Max Tool Weight | kg | 7 | 7 | 11 | |

| Max Tool Dia. - Adj. Occupied | mm | 80 | 75 | 95 | |

| Max Tool Dia. - Adj. Empty | mm | 125 | 125 | 200 | |

| Max Tool Length | mm | 250 | 300 | 400 | |

| DIMENSIONS | Machine Weight | kg | 3,500 | 5,500 | 13,500 |

| Width | mm | 1500 | 2420 | 3100 | |

| Depth | mm | 2500 | 3600 | 6100 | |

| Height | mm | 2450 | 2750 | 3000 | |

| Current | kVA | 30 | 40 | 45 | |

Jupiter partners with the world’s leading CNC system providers to deliver whatever platform you prefer.